Over the years, cost-effective and high-force hydraulic cylinders have been a popular choice for many types of automation machinery in factories and other facilities. More recently, electric rod actuators have also gained popularity because of their reliability, flexibility, and precision combined with high force capacity.

As a result of these developments in electric actuators, there has been a debate about whether to use electric linear actuators vs. hydraulic cylinders in various environments. Below, we’ll go over the benefits of each technology and how to choose the right one for your application.

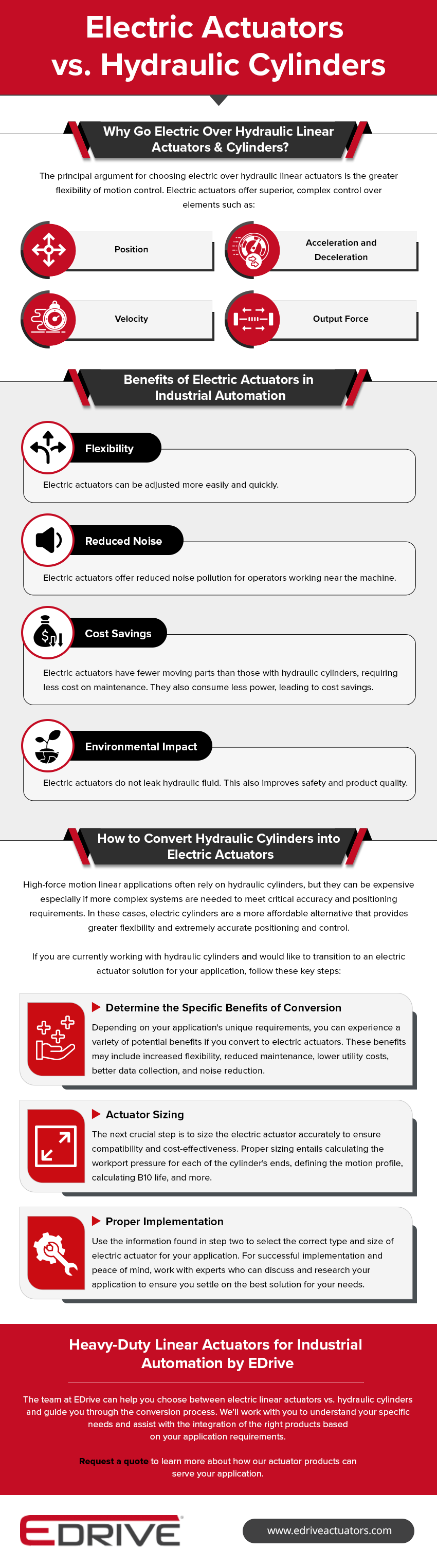

Why Go Electric Over Hydraulic Linear Actuators & Cylinders?

The principal argument for choosing electric over hydraulic linear actuators is the greater flexibility of motion control. Electric actuators offer superior, complex control over elements such as:

- Position

- Acceleration and deceleration

- Velocity

- Output force

Benefits of Electric Actuators in Industrial Automation

Flexibility. Electric actuators can be adjusted more easily and quickly.

Reduced Noise. Electric actuators offer reduced noise pollution for operators working near the machine.

Cost Savings. Electric actuator have fewer moving parts than those with hydraulic cylinders, requiring less cost on maintenance. They also consume less power, leading to cost savings.

Environmental Impact. Electric actuators do not leak hydraulic fluid. This also improves safety and product quality.

How to Convert Hydraulic Cylinders into Electric Actuators

High-force motion linear applications often rely on hydraulic cylinders, but they can be expensive especially if more complex systems are needed to meet critical accuracy and positioning requirements. In these cases, electric cylinders are a more affordable alternative that provides greater flexibility and extremely accurate positioning and control.

If you are currently working with hydraulic cylinders and would like to transition to an electric actuator solution for your application, follow these key steps:

- Determine the specific benefits of conversion: Depending on your application's unique requirements, you can experience a variety of potential benefits if you convert to electric actuators. These benefits may include increased flexibility, reduced maintenance, lower utility costs, better data collection, and noise reduction.

- Actuator sizing: The next crucial step is to size the electric actuator accurately to ensure compatibility and cost-effectiveness. Proper sizing entails calculating the workport pressure for each of the cylinder's ends, defining the motion profile, calculating B10 life, and more.

- Proper implementation: Use the information found in step two to select the correct type and size of electric actuator for your application. For successful implementation and peace of mind, work with experts who can discuss and research your application to ensure you settle on the best solution for your needs.

Heavy-Duty Linear Actuators for Industrial Automation by EDrive

The team at EDrive can help you choose between electric linear actuators vs. hydraulic cylinders and guide you through the conversion process. We'll work with you to understand your specific needs and assist with the integration of the right products based on your application requirements.

Our heavy-duty electric linear actuators work in many rugged applications across a range of industries, such as the agricultural, defense, automotive, forestry and lumber, motion simulation and entertainment, packaging, and food and beverage markets. Our standard product offerings come with flexible motor options, a high-capacity precision ball screw, a sealed chamber design, long service life, and various customizable options.

Request a quote to learn more about how our actuator products can serve your application.