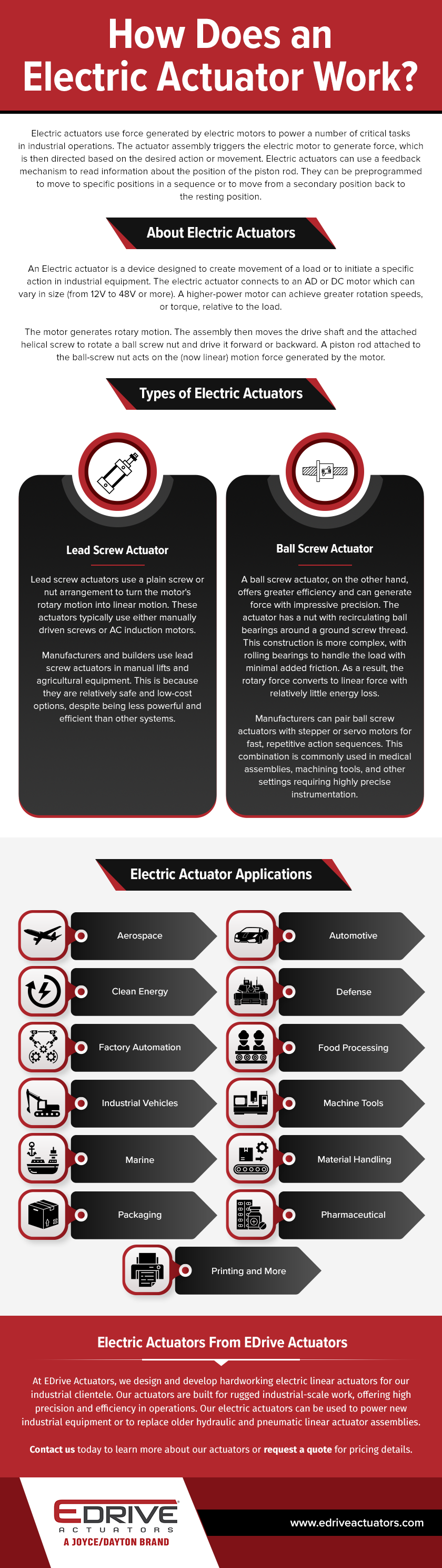

Electric actuators use force generated by electric motors to power a number of critical tasks in industrial operations. The actuator assembly triggers the electric motor to generate force, which is then directed based on the desired action or movement. Electric actuators can use a feedback mechanism to read information about the position of the piston rod. They can be preprogrammed to move to specific positions in a sequence or to move from a secondary position back to the resting position.

We’ll highlight some of the top electric actuators currently available and the benefits they are designed to offer, so you get the most out of your equipment. Read on to learn about these high-performing devices and how EDrive Actuators can help you select the best actuator for your application.

About Electric Actuators

An Electric actuator is a device designed to create movement of a load or to initiate a specific action in industrial equipment. The electric actuator connects to an AD or DC motor which can vary in size (from 12V to 48V or more). A higher-power motor can achieve greater rotation speeds, or torque, relative to the load.

The motor generates rotary motion. The assembly then moves the drive shaft and the attached helical screw to rotate a ball screw nut and drive it forward or backward. A piston rod attached to the ball-screw nut acts on the (now linear) motion force generated by the motor.

Most electric actuators follow these key principles. However, a wide selection of electric actuators is available for applications requiring specific performance capabilities. We’ll cover some common kinds of electric actuators below.

Types of Electric Actuators

Two of the most commonly used types of electric actuators are lead screw actuators and ball screw actuators. Each offers unique benefits and performance capabilities.

Lead Screw Actuator

Lead screw actuators use a plain screw or nut arrangement to turn the motor's rotary motion into linear motion. These actuators typically use either manually driven screws or AC induction motors.

Manufacturers and builders use lead screw actuators in manual lifts and agricultural equipment. This is because they are relatively safe and low-cost options, despite being less powerful and efficient than other systems.

Ball Screw Actuator

A ball screw actuator, on the other hand, offers greater efficiency and can generate force with impressive precision. The actuator has a nut with recirculating ball bearings around a ground screw thread. This construction is more complex, with rolling bearings to handle the load with minimal added friction. As a result, the rotary force converts to linear force with relatively little energy loss.

Manufacturers can pair ball screw actuators with stepper or servo motors for fast, repetitive action sequences. This combination is commonly used in medical assemblies, machining tools, and other settings requiring highly precise instrumentation.

Electric linear actuators are popular assemblies among manufacturers and industrial organizations powering highly repetitive, automated tasks. Linear actuators offer accurate positioning during these repetitions. Their ball bearings also reduce friction and promote smooth operations, adding to the efficiency and long-term performance of the larger system.

Electric Actuator Applications

Electric actuators are used in a variety of applications, from aerospace assemblies and industrial factory tools to consumer cars. At E-Drive Actuators, we can develop the right electric actuators for applications across all major industrial sectors. Common applications include:

- Aerospace

- Automotive

- Clean Energy

- Defense

- Factory Automation

- Food Processing

- Industrial Vehicles

- Machine Tools

- Marine

- Material Handling

- Packaging

- Pharmaceutical

- Printing

- And More

Electric Actuators From EDrive Actuators

At EDrive Actuators, we design and develop hardworking electric linear actuators for our industrial clientele. Our actuators are built for rugged industrial-scale work, offering high precision and efficiency in operations. Our electric actuators can be used to power new industrial equipment or to replace older hydraulic and pneumatic linear actuator assemblies.

Contact us today to learn more about our actuators or request a quote for pricing details.